SOLUTION

Pyrolysis Technology

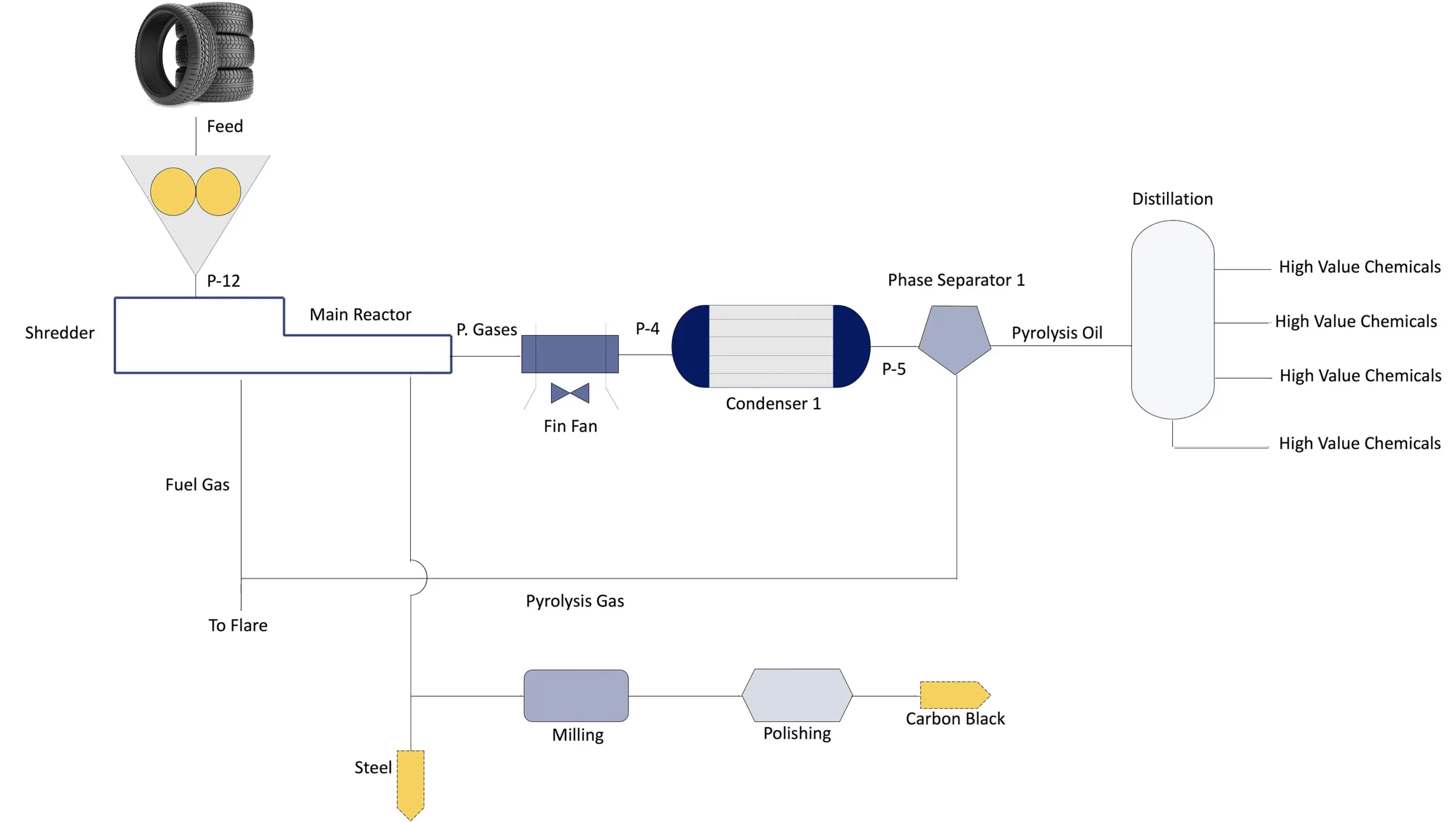

InnoVent Renewables, in collaboration with a world renowned research facility, has developed a continuous pyrolysis technology that processes waste tires into valuable renewable fuels and high value petrochemicals.

QUALITY

InnoVent Products

Our products attract carbon credits and carbon offsets as global demand increases for circular products and environmentally conscientious manufacturing to address waste. Our products include high quality renewable pyrolysis oil (PyOil), aromatics, circular/recovered carbon black (rCB), and steel wire. PyOil, can be sold as fuel oil, off-road diesel, or used as a feedstock to crude blending; and contains a high percentage of valuable aromatic compounds which can be further extracted and sold at higher margins.

PyOilPyOil (also referred to as bio-crude or bio-oil) can be used as a lower carbon fuel oil, off-road diesel or as feed to ethylene crackers. With additional treatment, PyOil can be used as ultra-low sulfur diesel (ULSD).

PyGasFully recovered by-product used in petrochemical production.

rCBCarbon black is an elastomer-reinforcing agent in rubber applications (e.g. tire production). Portions of carbon black production can also be utilized for inks, coatings, dyes, as an electrical conductivity agent in batteries, or as an ultra-violet (UV) stabilizer and nanomaterials for heavy metal removals.

AromaticsFully recovered by-product used in petrochemical production.

Steel WireSteel wire is utilized as a fundamental building material, made primarily of iron alloyed with carbon. Pyrolysis steel wire can be used to manufacture metal abrasives, steel wire cut pellets and other basic steel materials.

PROCESS

Production Steps

Pyrolysis is a well-known versatile process and technique that’s applicable to waste tires, plastic, and various kinds of biomass (e.g.: sugarcane bagasse, corn husk).

The InnoVent team conducted product quality analysis in conjunction with a world renowned research facility and results were further validated and scaled up in 2022, using comprehensive process simulation software and pre-engineering design work for scale-up.

This resulted in an optimized and efficient “continuous” process for extraction of valuable products from waste tires, biomass and HDPE plastic.